- About

- Academics

-

Undergraduate Programs

- Civil and Environmental Engineering

- Architecture and Architectural Engineering

- Mechanical Engineering

- Industrial Engineering

- Energy Resources Engineering

- Nuclear Engineering

- Materials Science and Engineering

- Electrical and Computer Engineering

- Naval Architecture and Ocean Engineering

- Computer Science and Engineering

- Aerospace Engineering

- Chemical and Biological Engineering

-

Graduate Programs

- Civil and Environmental Engineering

- Architecture and Architectural Engineering

- Mechanical Engineering

- Industrial Engineering

- Energy Systems Engineering

- Materials Science and Engineering

- Electrical and Computer Engineering

- Naval Architecture and Ocean Engineering

- Computer Science and Engineering

- Chemical and Biological Engineering

- Aerospace Engineering

- Interdisciplinary Program in Technology, Management, Economics and Policy

- Interdisciplinary Program in Urban Design

- Interdisciplinary Program in Bioengineering

- Interdisciplinary Program in Artificial Intelligence

- Interdisciplinary Program in Intelligent Space and Aerospace Systems

- Chemical Convergence for Energy and Environment Major

- Multiscale Mechanics Design Major

- Hybrid Materials Major

- Double Major Program

- Open Programs

-

Undergraduate Programs

- Research

- Campus Life

- Communication

- Prospective Students

- International Office

“Worldwide Nuclear Power Plant Cracks Are All In Our Hands”… Professor Kwon Dongil Gets Accepted by US Nuclear Technology Standards

-

Uploaded by

관리자

-

Upload Date

2018.04.09

-

Views

661

“Worldwide Nuclear Power Plant Cracks Are All In Our Hands”…

Professor Kwon Dongil Gets Accepted by US Nuclear Technology Standards

Professor Kwon Dongil Gets Accepted by US Nuclear Technology Standards

- “Stress Measurement Technology” Certified by US Nuclear Technology Standards

- Applications to Earthquake Prediction and Other Areas Anticipated

- Applications to Earthquake Prediction and Other Areas Anticipated

▲ SNU Department of Materials Science and Engineering Professor Kwon Dongil

Durability Testing Technology developed by Korean scientists has been certified by world’s strictest Nuclear Technology Standards of US.

SNU College of Engineering (Dean Cha Kook-Heon) announces that the “Stress (force per unit area within material due to continuous exertion of an external force) Measurement Technology” created by Professor Kwon Dongil from the Department of Materials Science and Engineering has been accepted by the American Society of Mechanical Engineers (ASME) to be the technological standard for testing the welds of reactor pressure vessels.

ASME’s Nuclear Technology Standards is currently the global standard for nuclear power plant design. In the area of nuclear power, the Korea Electric Power Industry Code (KEPIC) also implements ASME’s standards.

The reactor power vessel, as a main component of the nuclear power plant, holds steam generators that boil water using the heat produced by nuclear reactor core. Damage of this vessel leads to the leakage of harmful radioactive radiation. Thus, the inspection criteria of the reactor power vessel are stricter than any other components of the plant. The Nuclear Regulatory Commission (NRC) especially points out that welds of the vessels are the weakest points. At over 1000 degrees Celsius, the expansion ratio of weld material differs from other parts. Hence, unbalanced force transforms the shape of the welds, making them vulnerable to cracks and breaches – specifically this force is called residual stress.

Nuclear power plants around the world eliminate this residual stress through the post-annealing treatment, which involves dispersing the biased heat energy by applying heat of lower temperature after the welding procedure. Using the testing technology developed by Professor Kwon’s research team, residual stress can be measured whilst welding and the whole post-annealing treatment can be eliminated. This not only guarantees a higher nuclear safety, but also reduces plant installation cost.

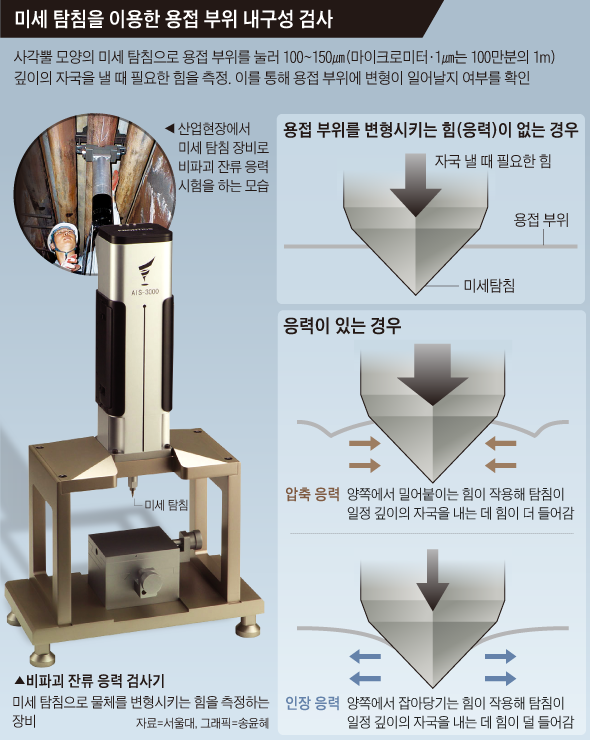

Professor Kwon points out that the “core of this new technology is the injection of micro-needle into welds to calculate residual stress.” This pyramid-shaped needle has a height of only 300㎛ (one micrometer is equivalent to millionth of a meter) and is made of the hardest and most rigid material of diamond.

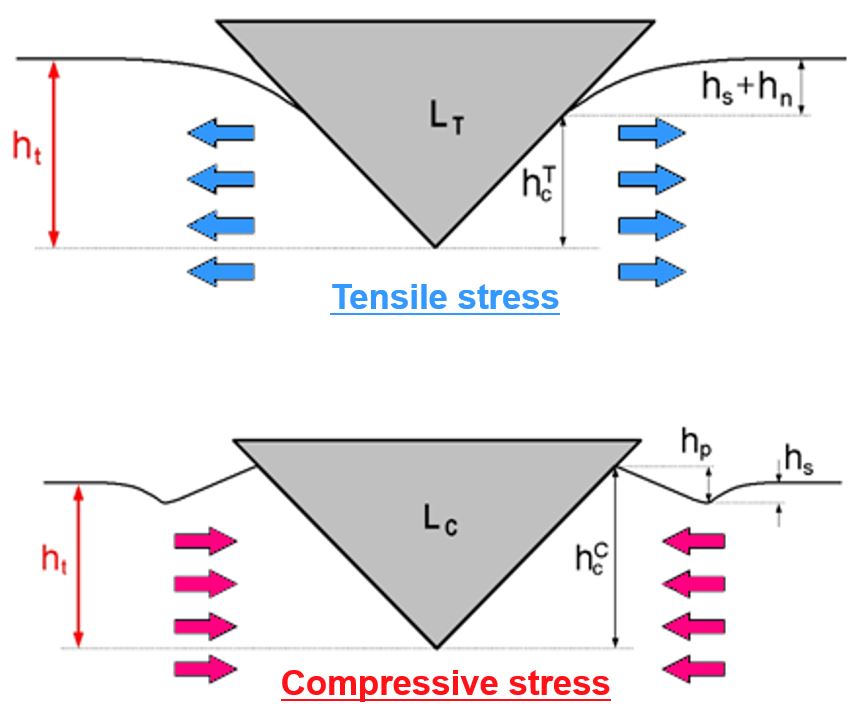

During the test, the micro-needle leaves a 100~150㎛ dent on the welds. By comparing the amount of force applied to welds to the standard amount of force needed to leave a dent on the welding material, it is possible to determine whether breaches may happen or not.

Director Lee Bong-Sang of Korea Atomic Energy Research Institute (KAERI)’s Nuclear Materials Research Team states, “Unlike conventional tests that involve removing metal pieces from welds or conducting additional annealing procedure, this new method can easily and accurately measure the possibility of deformation on site.”

Kwon states that this “new technology is already being practiced during safety inspections of gas pipelines in US and petrochemical plants in Korea.” He visions that “the certification will be the trigger to extending the application range of this technology to areas like earthquake prediction.”

Micro-needles can be used during various accident investigations. Kwon is already known as the “CSI of Engineering” around the world. He has revealed that the cause of the 2010 October Tower Crane Collapse at Hapjeong-dong, Seoul was due to the defect of bolts that connect crane’s jib (horizontal axis) and tower (vertical axis). Back then, too, penetration of micro-needle into bolts uncovered the lack of proper heat treatment. In the following year, Kwon launched the Korean Society of Forensic Engineering with experts in safety technology to rear CSI engineers in Korea. At SNU, Professor Kwon established the Convergence Research Institute for Forensic Safety to co-investigate accident sites with the National Forensics Service.

▲ Principles of Durability Test Using Micro-Needles

▲ Result of Durability Test Using Micro-Needles

▲ Durability Test of Welds Using Micro-Needles