- About

- Academics

-

Undergraduate Programs

- Civil and Environmental Engineering

- Architecture and Architectural Engineering

- Mechanical Engineering

- Industrial Engineering

- Energy Resources Engineering

- Nuclear Engineering

- Materials Science and Engineering

- Electrical and Computer Engineering

- Naval Architecture and Ocean Engineering

- Computer Science and Engineering

- Aerospace Engineering

- Chemical and Biological Engineering

-

Graduate Programs

- Civil and Environmental Engineering

- Architecture and Architectural Engineering

- Mechanical Engineering

- Industrial Engineering

- Energy Systems Engineering

- Materials Science and Engineering

- Electrical and Computer Engineering

- Naval Architecture and Ocean Engineering

- Computer Science and Engineering

- Chemical and Biological Engineering

- Aerospace Engineering

- Interdisciplinary Program in Technology, Management, Economics and Policy

- Interdisciplinary Program in Urban Design

- Interdisciplinary Program in Bioengineering

- Interdisciplinary Program in Artificial Intelligence

- Interdisciplinary Program in Intelligent Space and Aerospace Systems

- Chemical Convergence for Energy and Environment Major

- Multiscale Mechanics Design Major

- Hybrid Materials Major

- Double Major Program

- Open Programs

-

Undergraduate Programs

- Research

- Campus Life

- Communication

- Prospective Students

- International Office

Research Team Led by Professor Yongtaek Hong Develops Highly Customizable All Solution-Processed Polymer Light Emitting Diodes

-

Uploaded by

관리자

-

Upload Date

2019.08.20

-

Views

405

Research Team Led by Professor Yongtaek Hong Develops Highly Customizable All Solution-Processed Polymer Light Emitting Diodes

- Possible Applications to Developing Low-cost Large Area Display

▲ Professor Hong’s Team: (From Left) Professor Yongtaek Hong, Researcher Jongjang Park

Korean researchers developed a crucial technology to customize polymer light-emitting diodes for future displays.

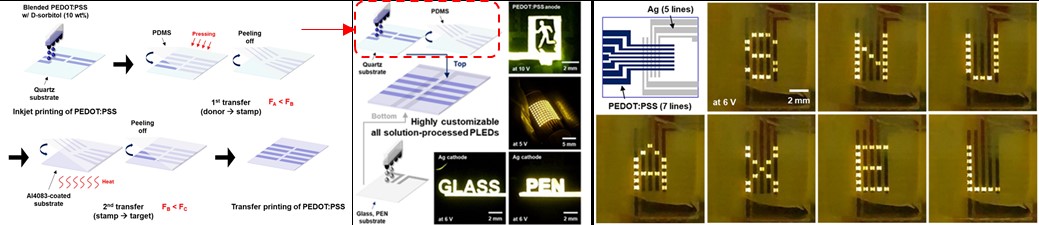

SNU College of Engineering (Dean Kookheon Char) announced on 27th that the research team (including Researcher Jongjang Park) led by Professor Yongtaek Hong of the Department of Electrical and Computer Engineering developed all solution-processed polymer light emitting diodes (LED). The team’s use of ink jet printing allowed the production of highly customizable diodes with reflective Ag (silver) electrodes and transparent, conductive polymer electrodes.

Currently, there are active researches being conducted on large-area, low-cost future displays including window display, ubiquitous information display, and wearable & disposable display. However, researchers face difficulties in producing specific mask for different designs through the conventional vacuum coating method.

Hence, Hong’s team introduced inkjet printing to yield high-resolution electrode patterns. They first ink-jetted reflective Ag onto a transparent substrate glass or plastic to complete the bottom electrode. Then, they inserted various layers including the emission layer onto the bottom electrode. They finished their device with a transfer printed transparent, conductive polymer top electrode.

This transfer printing method enabled Hong’s team to resolve the issue of bottom organic layer damage caused during solution processing. In order to maximize the properties of transfer, they created a special type of conductive polymer ink with viscosity and surface tension. This was applied to control the viscosity between electrodes and layers.

Finally, the team also developed various forms of light emitting logos and narrow-trench light emitting diode arrays on glass and plastic boards and the first all-solution processed passive matrix OLED. Thus, they demonstrated that customizable display devices can be created with the much simpler display technique suggested by them.

Professor Hong explained, “This research not only developed an all-solution processed polymer light-emitting diode displays, but also succeeded in designing highly-efficient customizable light-emitting device. We believe the continuous development of manufacturing technologies for large-area, low-cost display can produce various future displays.”

The research findings had been published online on the Advanced Functional Materials as of the 20th of June. This research was supported by the “Support Plan for the Development of Core Technologies for Future Display Materials and Device” of the Ministry of Trade, Industry and Energy and the Korean Information Display Society (KIDS) and funded by the Samsung Display.

▲ (From Left) Process of Creating Conductive Polymer Thin Film Via Inkjet and Transfer Printing,

An Example of Highly Customizable All-Solution Processed Polymer Light-Emitting Diode Displays,

Array of All-Solution Processed Passive Matrix OLED