- About

- Academics

-

Undergraduate Programs

- Civil and Environmental Engineering

- Architecture and Architectural Engineering

- Mechanical Engineering

- Industrial Engineering

- Energy Resources Engineering

- Nuclear Engineering

- Materials Science and Engineering

- Electrical and Computer Engineering

- Naval Architecture and Ocean Engineering

- Computer Science and Engineering

- Aerospace Engineering

- Chemical and Biological Engineering

-

Graduate Programs

- Civil and Environmental Engineering

- Architecture and Architectural Engineering

- Mechanical Engineering

- Industrial Engineering

- Energy Systems Engineering

- Materials Science and Engineering

- Electrical and Computer Engineering

- Naval Architecture and Ocean Engineering

- Computer Science and Engineering

- Chemical and Biological Engineering

- Aerospace Engineering

- Interdisciplinary Program in Technology, Management, Economics and Policy

- Interdisciplinary Program in Urban Design

- Interdisciplinary Program in Bioengineering

- Interdisciplinary Program in Artificial Intelligence

- Interdisciplinary Program in Intelligent Space and Aerospace Systems

- Chemical Convergence for Energy and Environment Major

- Multiscale Mechanics Design Major

- Hybrid Materials Major

- Double Major Program

- Open Programs

-

Undergraduate Programs

- Research

- Campus Life

- Communication

- Prospective Students

- International Office

Industrial Digital Transformation in Response to Post-Corona

-

Uploaded by

관리자

-

Upload Date

2020.09.16

-

Views

794

Industrial Digital Transformation in Response to Post-Corona

Corona hit South Korea during a business trip to the U.S. in late February, and business companies hurried back home. Soon, the whole world began to panic amidst the chaos of Corona. From checking the number of confirmed patients and their movement routes every day, online meetings and classes to social distancing, wearing masks and washing our hands, our daily lives have changes a 180 degrees. Global crude demand and global commodity trading fell by 16.2% and 18.5% respectively compared to last year as of the second quarter of 2020 with the World Bank reporting in June that the global economic growth rate is expected to be -5.2 %, the worst since World War II. Governments have been trying to minimize the damage from corona by providing emergency disaster support to help heal the economic downturn. However, this is only an emergency measure rather than a fundamental solution to Corona. To date, Korea's preemptive action under the initiative of the government in response to Corona has generally been positively evaluated and there is an exemplary case of a "K-Quarantine" model that tests, tracks and manages Corona based on ICT.

Almost all quarantine experts are voicing the need for a long-term response to the Corona crisis. If the current economic slump continues in the long term, no company or country would be able to survive. In other words, Corona is the greatest crisis of this era! However, even in a crisis, there are always risks and opportunities that exist. If such risks are well overcome, there surely are chances for great opportunities. So far, the Republic of South Korea has overcome such risks. Therefore, analysis of risk and opportunity factors is very important to open up a successful post-corona era. Among them, the most important keywords are "non-face-to-face" and "digitalization." In our society and industry, non-face-to-face is a huge risk factor, and in order to overcome this, "digitalization" exists as an opportunity. It is right here where the answer to preparing for post-corona lies.

The basis of our economy is manufacturing. Our manufacturing industry was helpless against the damage caused by the Corona. Decreasing orders, clogging of export routes, the vicious cycle of difficulty in procuring major device parts while inventories continue to increase while at the same time, the collection of corporate loans have caused the suffering of further hardships. This led to an increase in unemployment, threatening the national economy. Despite the recent shift to daily quarantine, the operation rate of our industry has still decreased by 2~30% and concerns have begun to arise about reduction in work efficiency due to non-face-to-face or limited face-to-face work. The solution to this is 'digitalization,' or the transition to the digital age. We have already found the answer in the K-Quarantine model for the Corona situation. K-Quarantine is producing successful results through 'digital quarantine' that combines existing medical domain of quarantine knowledge with digital technology called ICT. In order to survive this highly uncertain Corona era and turn its risks into opportunities, digitalization of our manufacturing industry is not an option but a necessity.

Even before Corona, our manufacturing industry was already facing the challenges of digitalization. Digitalization was proposed with the expectation that it could increase the operational efficiency of manufacturing facilities, maximize the quality of manufacturing, and reduce accidents. However, digitalization, which requires considerable investment and experience, was not a must but more of a choice before the Corona crisis. Of course, it wasn't just a simple matter of investment. It was also the issue of changing the mindsets of stubborn experts that were involved knee-deep into the industry. This was not the first time that we realized that, unless it being the case of an indispensable situation, "people" were the biggest stumbling block regarding the huge shift to digitalization. The process of evolution into the industrial revolution era, the transition into to the electric car era and the transition into the renewable era have always been opposed, but it had always been a matter of time, not a matter of choice. In the end, the answer to the crisis of non-face-to-face partially face-to-face work is the shift to the opportunity of industrial digitalization (the fourth industrial revolution). Therefore, industrial digitalization will accelerate only when we eliminate the old conventional ways of thinking and reap the unprovoked resistance that humans create. This would be the way to create opportunities in the post-corona era.

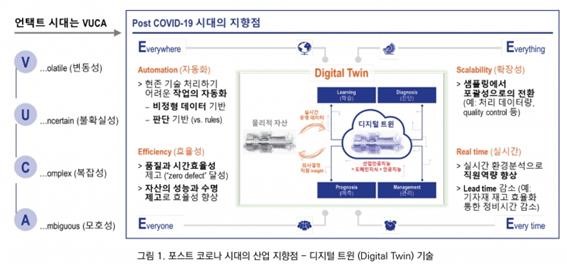

Picture 1 Post-Corona Era’s Industrial Orientation – Digital Twin Technology

Digitalization for each industrial group cannot be uniform. The industrial groups representing our country are automobiles, semiconductors, petrochemicals, power generation, transportation and national defense. In order to achieve successful digitalization in each industrial group, the characteristics of each industrial group must be well understood. The issues of each industrial group are as follows - mobility and quality for the automobile industry, operation rate and quality for the semiconductor industry, efficiency and industrial accidents for the petrochemical and power generation industry, passenger accidents and industrial accidents for transportation industry and the issue of new technology and durability for national defense. These issues are major performance indicators for each industry and digitalization can maximize these performance indicators. The industrial data acquisition and management systems, data analysis system, and performance index diagnosis and management systems related to each performance indicator can be carried out in a non-face-to-face or partially face-to-face manner through digitalization, which will be a catalyst to our competitiveness in the future. In addition, securing and managing industrial data for each industrial group requires great consideration regarding strategic and systematic aspects. Many companies already have a significant amount of industrial data, but their utilization level is less than 1%. In the digital age, industrial data is a huge resource. The low utilization of industrial data reflects that the utility value of resources is low. In the end, securing industrial data with high utility value is the first step into the digital era, and a strategic and systematic approach for this is needed. To provide an example, in the age of mobility, cars are just transportation tools. In the era of mobility, shared cars and self-driving cars will be the main focus, and Integrated Vehicle Health Management (IVHM) is a highly important digital technology. Since drivers of shared vehicles are not owners of the vehicles, they are not interested in or are less interested in the occurrence of any problems regarding the vehicle's condition.

This is expected to be a major challenge in terms of management. Such a problem was observed in 'Seoul Bike', a shared bicycle system operated by the Seoul Metropolitan Government. According to Seoul Metropolitan Council member Seung Woo Chu, 32% of Seoul Bikes were reported to be out of operation due to terminal or mechanical failure. This is the loophole within a shared economy. In other words, as the ownership economy changes to a shared economy, autonomous management is difficult, and digital technology is urgently needed to solve this problem. The development of IVHM technology that can systematically define data measurement points and optimize the management of shared vehicles through data measurement is desperately needed. Meanwhile, digitalization is also wriggling in the power generation and petrochemical industries. Until now, much of industrial data has been acquired and managed either peripherally or fragmentarily.

Thus, recently, integrated and continuous industry data acquisition and management have been attempted to take place, and the technology that makes this possible is the Digital Twin (Picture 1). Digital Twin enables anyone to systematically measure, learn, diagnose, predict, and manage industrial data obtained from industrial facilities from anywhere even if they do not go directly to industrial facilities, thereby ensuring at-a-glance operation and robustness of industrial facilities at any time, and taking remote action accordingly. In the power supply and petrochemical industries, Digital Twin maximizes productivity by optimizing the management of old facilities, enables optimal management of industrial facilities with non-face-to-face/partially face-to-face work, while at the same time reducing industrial accidents and formalizing tacit knowledge of field experts. In other words, Digital Twin technology can easily understand, analyze and manage facility operation and management in a cyber environment without the help of existing facility operation and management experts. In Korea, which is lacking of underground resources, industrial data is an infinite new resource in the digital age and an opportunity to become a top-notch country. Further, this should continue the future of our industry in the post-corona era.

The Digital Twin industry is growing rapidly with an average annual growth rate of 32%. Our country has the best conditions for Digital Twin. It is the mecca for the manufacturing industry with the world's best ICT technology and has excellent human resources for combining new technologies. In the future, the Corona era will open up a new industrial trend: the Digital Twin era. In response, we should lead the Digital Twin standard model for each industrial group, just as we have presented the K-Quarantine model in response to Corona. To successfully establish Digital Twin in various industries, technical and business attempts in various forms such as Internet of Things, Industrial Artificial Intelligence, Health Prediction and Management, Augmented Reality, and Integrated Asset Management are needed. In addition to the fourth industrial revolution based on industrial data, Digital Twin can evolve into various digital business models. In addition, the formation of related industrial ecosystems is very important for industrial completion. This is very closely related to the recent digital New Deal announced by the government, and it is necessary to establish an industrial ecosystem such as industrial data measuring companies, telecommunication companies, cloud companies, and industrial big data management companies to establish an industrial data acquisition system. This refers to the construction of an industrial data dam. Another digital New Deal policy, Digital Twin, requires the establishment of an ecosystem of industrial artificial intelligence (AI) companies, industrial domain (design, manufacturing, operation, maintenance) technology companies, and soundness prediction and management companies. Further, besides these private-level efforts, we need institutional and financial support at the government level, which is necessary to foster high-quality human resources in related technologies and to support legislation. Therefore, in such an untact era, the transition to "digital Korea" is not our choice but a necessity, and now we must meet a new Republic of South Korea.

Original Article: http://www.sforum.co.kr/2019/community/community_010100.html?bmain=view&uid=4