- About

- Academics

-

Undergraduate Programs

- Civil and Environmental Engineering

- Architecture and Architectural Engineering

- Mechanical Engineering

- Industrial Engineering

- Energy Resources Engineering

- Nuclear Engineering

- Materials Science and Engineering

- Electrical and Computer Engineering

- Naval Architecture and Ocean Engineering

- Computer Science and Engineering

- Aerospace Engineering

- Chemical and Biological Engineering

-

Graduate Programs

- Civil and Environmental Engineering

- Architecture and Architectural Engineering

- Mechanical Engineering

- Industrial Engineering

- Energy Systems Engineering

- Materials Science and Engineering

- Electrical and Computer Engineering

- Naval Architecture and Ocean Engineering

- Computer Science and Engineering

- Chemical and Biological Engineering

- Aerospace Engineering

- Interdisciplinary Program in Technology, Management, Economics and Policy

- Interdisciplinary Program in Urban Design

- Interdisciplinary Program in Bioengineering

- Interdisciplinary Program in Artificial Intelligence

- Interdisciplinary Program in Intelligent Space and Aerospace Systems

- Chemical Convergence for Energy and Environment Major

- Multiscale Mechanics Design Major

- Hybrid Materials Major

- Double Major Program

- Open Programs

-

Undergraduate Programs

- Campus Life

- Communication

- Prospective Students

- International Office

News

Development of Next-Generation Fiber-Based Human-Machine Interface (HMI) Bioelectrodes

-

Uploaded by

대외협력실

-

Upload Date

2024.08.05

-

Views

230

Development of Next-Generation Fiber-Based Human-Machine Interface (HMI) Bioelectrodes

Researchers Develop Next-Generation Wearable Bioelectrodes and Electronic Device Patterning Technology on Breathable Fiber Substrates

Necessity of the Research Flexible electronic devices based on electrospun* nanofiber membranes(ENM) are attracting significant attention due to their high biocompatibility and excellent mechanical performance. However, patterning conductive materials on fiber substrates typically requires expensive vacuum equipment or additional processes to create separate masks.

Research Achievements/Expectations To address this, a collaborative research team led by Professor Seung Hwan Ko of the Department of Mechanical Engineering at Seoul National University and Professor C-Yoon Kim of Konkuk University developed a system that induces efficient fluid flow using capillary action by placing a carbon paper support under the nanofiber membrane, enabling the filtration process without the need for vacuum equipment. This approach enhances mechanical stability by strongly bonding nanowires** and substrates through the photothermal effects*** of lasers during the post-processing stage. Additionally, the system demonstrated that circuits remained stable even under strong ultrasonic treatment and that the patterns on the substrate remained intact when manually pulled. The research team validated the strengths of their developed process system and outcomes through various applications, including an in vivo epicardial signal recording ECG electrode, an epidermal electrochemical biosensor, and customized epidermal electromyography (EMG)-based human–machine interface (HMI).

Research Content Overview

o A printing technology capable of patterning electrodes on soft nanofibers has been developed in South Korea.

o A collaborative research team led by Professor Seung Hwan Ko of Seoul National University and Professor C-Yoon Kim of Konkuk University (first co-authors: Master's student Hyeokjun Yoon, Dr. Joonhwa Choi, and Dr. Jin Kim) has developed a direct metal nanowire patterning method based on filtration using a dispenser system.

Background

o The potential of the electrospun nanofiber membrane (ENM)-based soft electronics in epidermal bioelectronics has gained huge attention with their conformal compatibility with the human body and associated performance improvements.

o However, patterning conductive materials on fiber substrates typically requires expensive vacuum equipment or additional processes to create separate masks.

Results

o In response, the research team developed a system that enables the filtration process without the need for costly vacuum equipment by placing a carbon paper support under the nanofiber membrane, inducing efficient fluid flow through capillary action.

o Using this system, the nanowires and substrates can be strongly bonded through the photothermal effects of lasers during the post-processing stage, enhancing mechanical stability. The system also demonstrated that circuits remained stable under strong ultrasonic treatment and that the patterns on the substrate remained intact when manually pulled.

o The research team validated the strengths of their developed process system and outcomes through various applications, including an in vivo epicardial signal recording ECG electrode, an epidermal electrochemical biosensor, and customized epidermal electromyography (EMG)-based human–machine interface (HMI). Additionally, this research has opened up possibilities for efficiently fabricating electronic devices with high stretchability, breathability, and conductivity, demonstrating potential applications in various healthcare and medical fields.

o Supported by the National Research Foundation of Korea(NRF) and Korea Institute for Advancement of Technology(KIAT) grant funded by the Korea Government(MOTIE), this research was published in the internationally renowned journal in the field of materials science, Advanced Functional Materials(AFM), on May 29 of this year.

Explanation of terms

*Electrospun: A process that uses a high-voltage electric field to spin polymer solutions or melts into fine fibers.

**Nanowire: A one-dimensional conductive material with a diameter at the nanometer scale and a very long length.

***Photothermal Effect: The phenomenon where specific materials absorb light and convert it into heat.

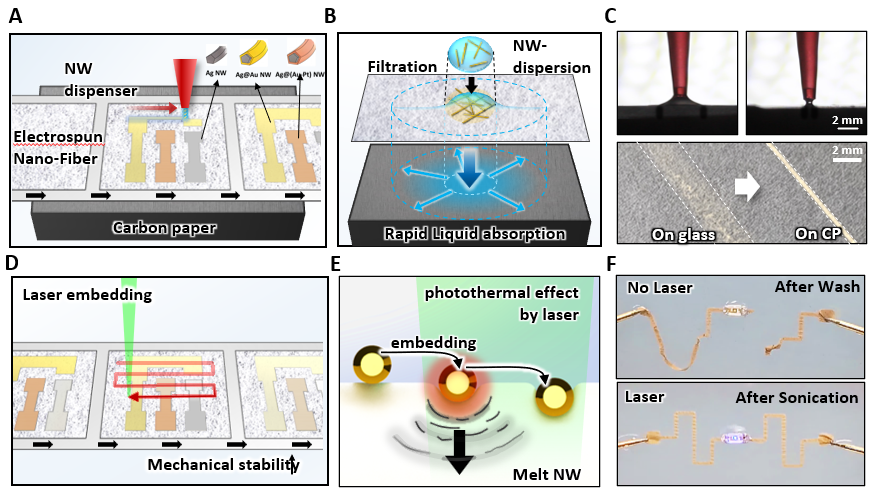

Figure 1: Micro-patterning Process of Conductive Hydrogel using Laser

(A) A local filtration-based nanowire printing process on electrospun nanofiber membranes (ENM) utilizing the capillary action of carbon paper.

(B) The rapid liquid drainage effect by carbon paper prevents nanowire ink from spreading on the ENM, enabling concentrated nanowire printing in narrow areas.

(C) Significant differences in linewidth and uniformity of nanowire traces printed on ENM when placed on glass versus carbon paper.

(D) Laser embedding process to enhance the mechanical stability of the nanowire (NW)–eTPU interface.

(E) Embedding of nanowires due to the photothermal effect of the laser.

(F) Washing durability test showing improved mechanical stability of the NW-eTPU interface after laser treatment.

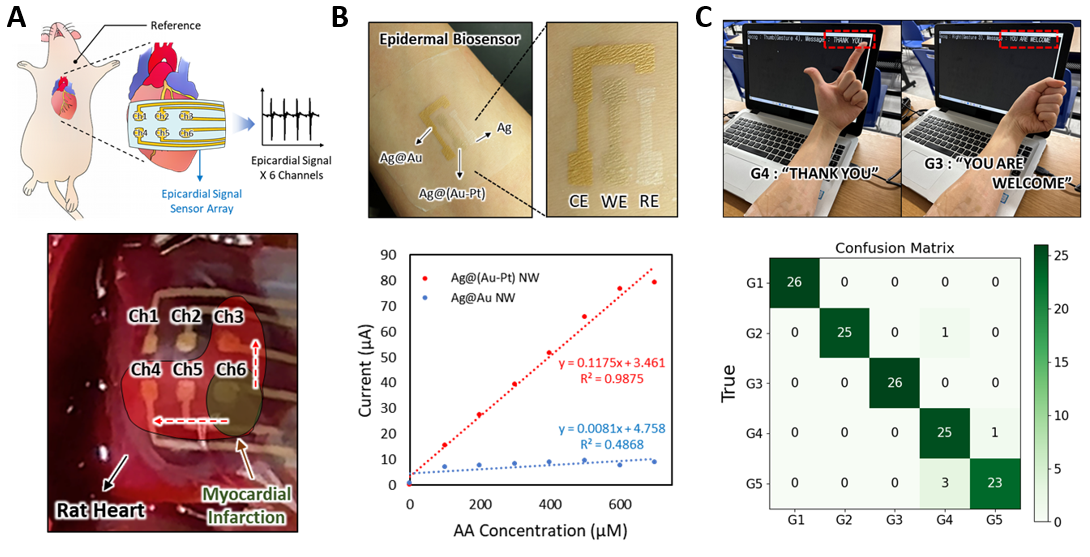

Figure 2: Various Biosensor Applications Developed through the Dispensing Process

(A) Heart of a rat fitted with a 6-channel ECG sensor.

(B) Detection of ascorbic acid using electrochemical sensors made by dispensing silver nanowires, silver-gold core-shell nanowires, and silver-gold-platinum alloy nanowires.

(C) Customized electromyography (EMG)-based human-machine interface (HMI).